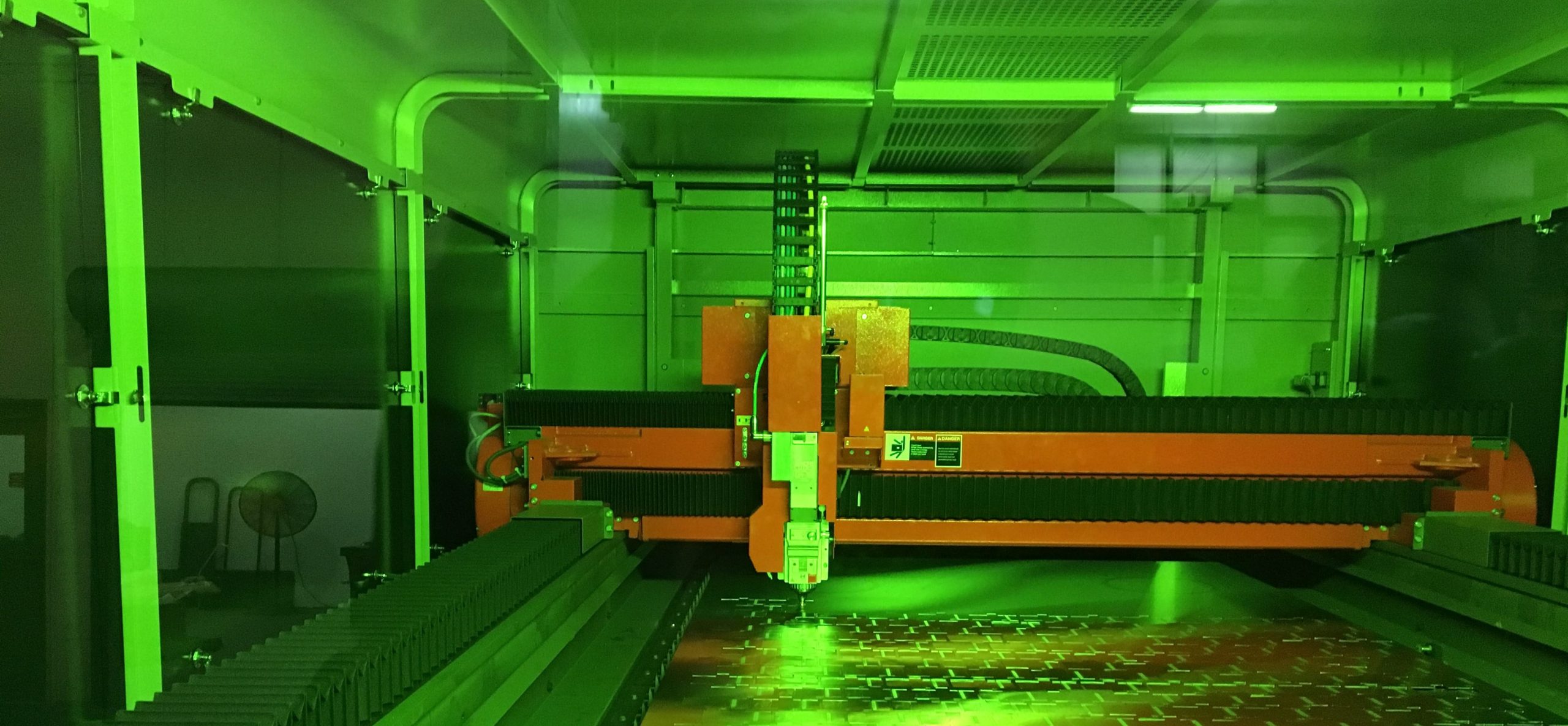

The Bystronic fiber laser delivers increased power and higher cutting precision than a 4kW fiber laser — for example, it can cut 1/8-inch stainless steel sheet metal up to 70 percent faster. The machine can perform intricate cuts that aren’t possible with less sophisticated machinery, doing so to create round and square shapes, angled and channel cuts and even non-traditional shapes. The 6kW fiber laser also eliminates the need for slower, less accurate applications such as metering, sawing, drilling and punching.

Besides faster fiber laser cutting, this revolutionary machine delivers the following: