Metal bending and forming refers to reshaping materials with various presses. Using computer numerical control (CNC) equipment introduces more accuracy to the process. While a human operator still oversees the machine, CNC presses allow computer software to control and guide the presses.

Caldera Manufacturing is a trusted and strategic business partner for CNC bending and forming in Pennsylvania and beyond. As a complete contract manufacturing group, we have a highly skilled team that demonstrates a passion for quality and service that distinguishes us from others. Our ISO 9001:2015 certification attests to our commitment to quality, and our innovation helps manufacturers in many industries make custom-designed projects a reality.

Advantages of CNC bending and forming include:

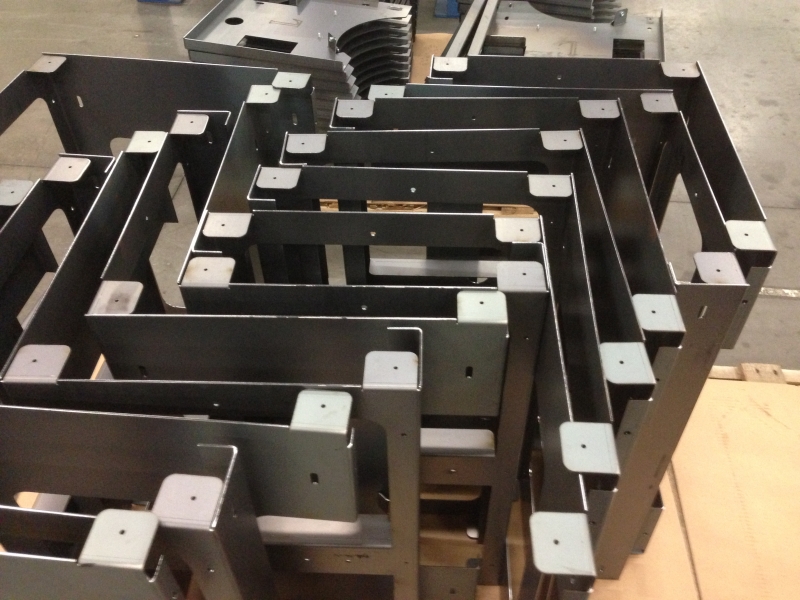

Caldera Manufacturing has equipped our 120,000-square-foot facility with advanced CNC presses to offer an unparalleled range of project possibilities. Our highly skilled operators form and reshape aluminum, carbon steel and stainless steel sheet metal. Capabilities include offset bending, air bending, U-bending and hemming.

Learn More

We have in-house engineering experts ready to provide value engineering services and project management expertise for many industries and products, such as:

CNC bending services and metal forming are also excellent solutions for other verticals and applications. Ask a specialist how Caldera Manufacturing can help you create a custom part for unique needs.