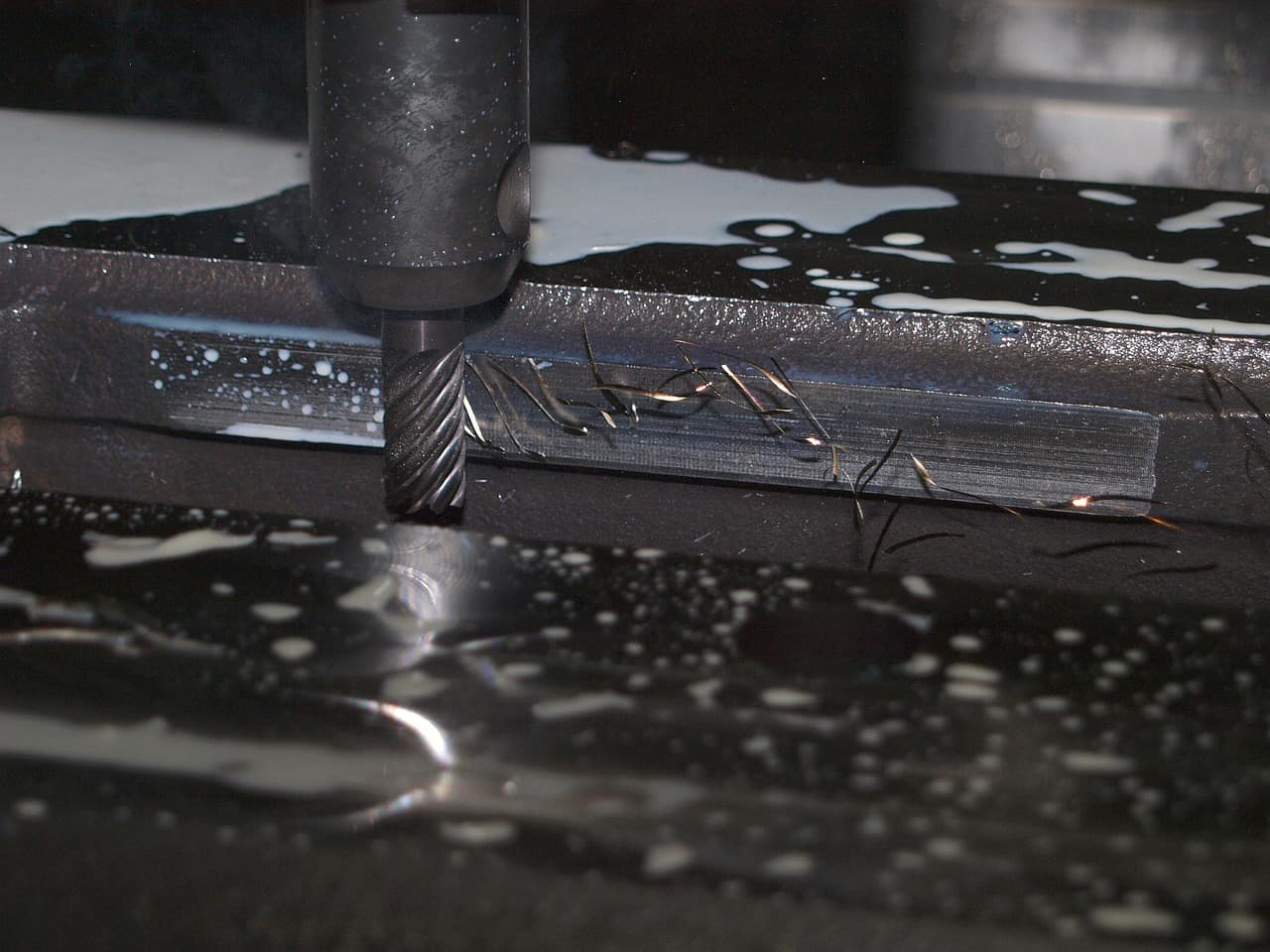

Computer numerical control (CNC) machining creates various product parts by harnessing technology’s power for accuracy. Powerful software positions and guides the tools or workpieces rather than a human operator. As a result, CNC-machined components offer high-precision solutions.

Caldera Manufacturing proudly offers professional CNC machining to manufacturers across many industries. As a partner in your company’s success, we prioritize your satisfaction through world-class service and superior results. Our highly skilled team works to meet strict quality standards in our ISO 9001:2015-certified facility and collaborates with you on custom component design and fabrication.

Learn More

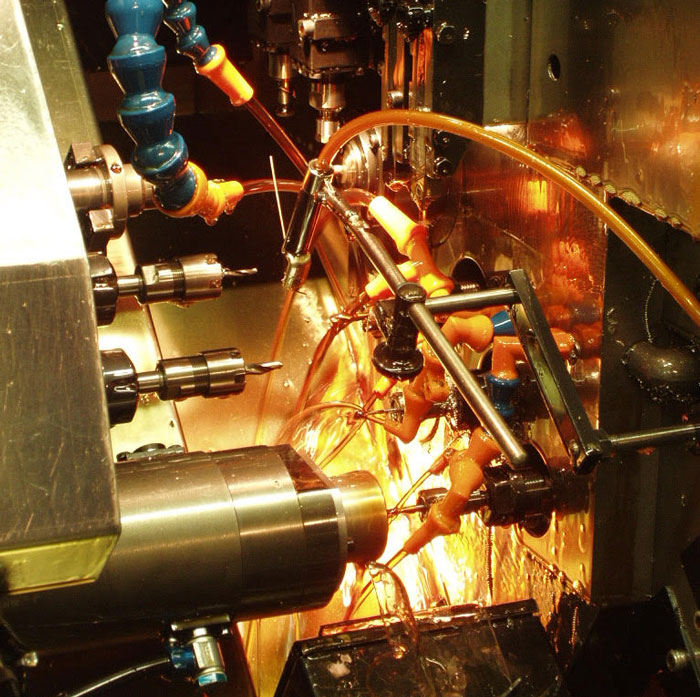

CNC machining is a trusted process for producing to-spec metal pieces with higher accuracy and more consistency than traditional machining equipment. It introduces more efficiency into the process since an operator can simultaneously oversee multiple machines without sacrificing quality. This equipment makes meeting tight deadlines possible, even with high-volume production and complex designs.

Caldera Manufacturing offers extensive expertise in several CNC machining capabilities.

CNC machined components provide value in applications and verticals like:

At Caldera Manufacturing, we also accommodate applications beyond those mentioned above. Our capabilities and advanced technology empower us to meet unique custom fabrication needs.