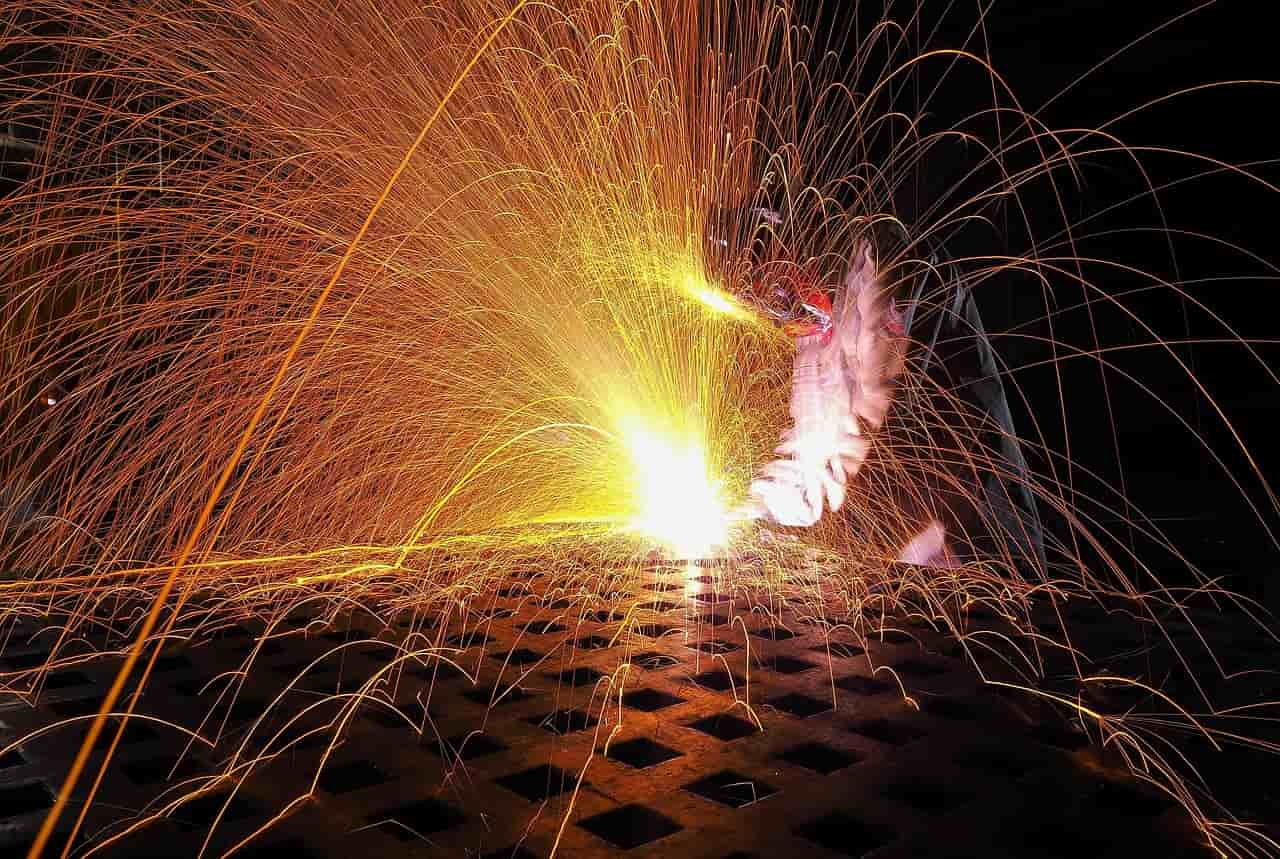

Caldera Manufacturing Group is an industry-leading welding contractor offering various options in manual and robotic welding processes. Whether your project requires MIG or TIG welding, we approach each project with the urgency and care needed to meet your specifications according to your timeline.

At Caldera, we maintain a full staff of American Welding Society (AWS)-certified welders to meet each project’s specific needs regardless of volume or complexity. We view our machines as a way to augment our human capabilities rather than replace them — and that’s how it should be.

Learn More

Our facilities enable us to use multiple welding techniques for maximum versatility. Take a look at our welding solutions.

Metal inert gas (MIG) welding is a basic arc welding process that joins metals together using a consumable filler metal. This material is typically an alloy formulated to join specific types of metals together, such as:

MIG welding is a simple process, making it a cost-effective option for high-volume projects with fast turnaround times. However, MIG welding is also slightly less reliable than TIG welding — and the melting of the filler material can produce dangerous fumes. Complex projects with more delicate components are less suited to this technique.

Our facility houses state-of-the-art equipment with an operational capacity for assembling many different components, from lightweight car parts to complex power generating devices. Industries we frequently serve include:

Whatever your project entails, we’ll help you find the right welding solutions. Contact us to discuss your specifications.